In 2019, we replaced all oil-burning boilers with gas boiling systems, resulting in a 63% decrease in CO2 emissions. The average CO2 emission rate was 136 tons/month from 2014 to 2017. After the replacement, we can control the CO2 emission rate at 50 tons/month. Also, by recycling dye materials, we have lowered 1456 tons of CO2 emissions each year.

By optimizing our steam pipeline’s decompression and heat preservation functions, we have successfully reduced the energy consumption from 304933 kWh/ year (avg. 2016 ~ 2018) to 173838 kWh/ year (avg. 2019 ~ 2021). Together with upgrading the air conditioning system, we have conserved 43% of energy consumption in total.

We have also saved 58.1% of water by increasing the number of blowdown heat recovery systems. The average of water usage has come down from originally 236214 tons/ year ( avg.2016 ~ 2018) to 98966 tons/ year ( avg.2019 ~ 2021).

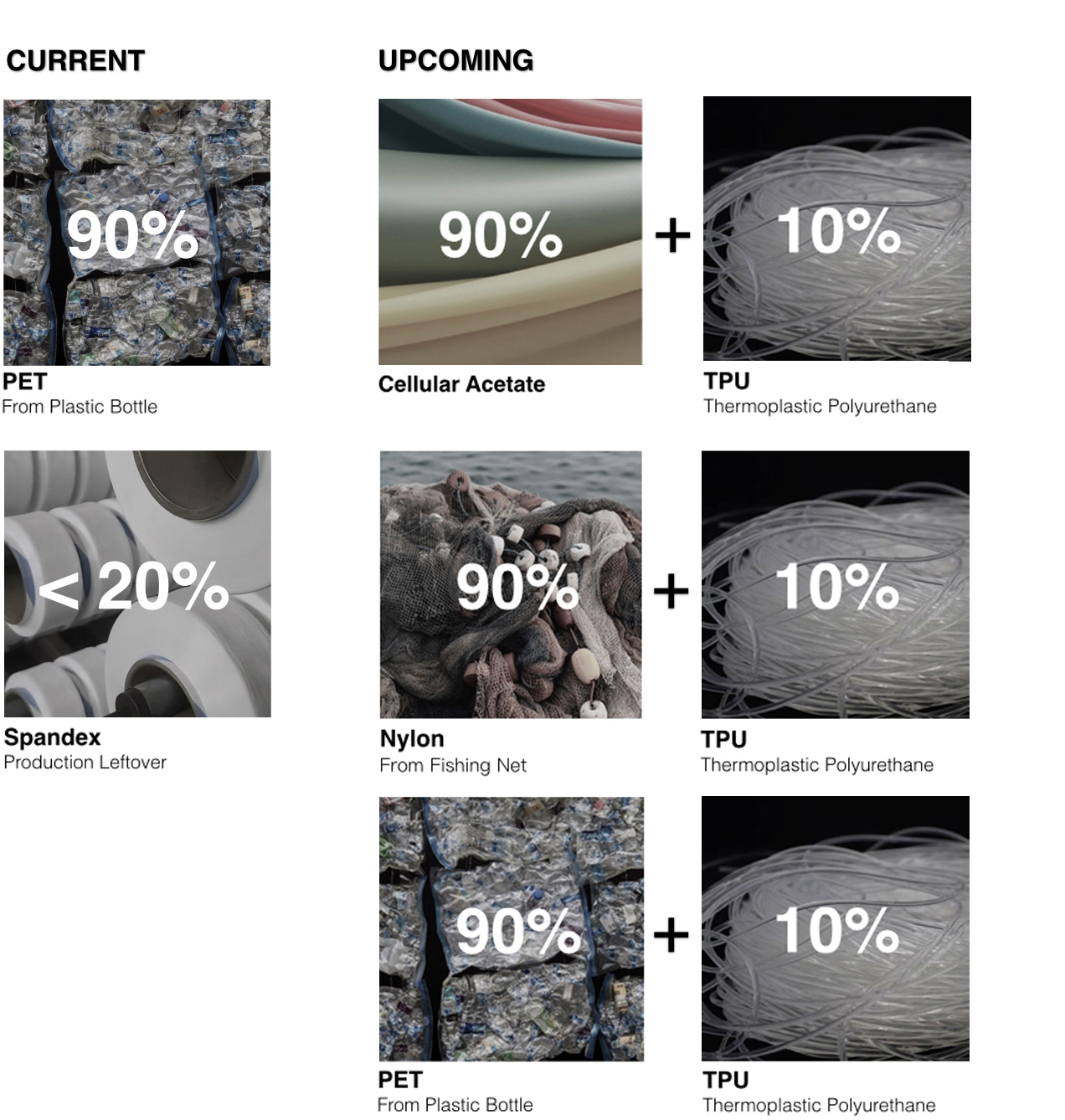

We are currently using recycled PET yarn from plastic bottles and recycled spandex from production leftovers as a replacement for original materials to produce the fabrics for our R-series. Estimated in 2023, we will develop sustainable products that source biodegradable compounds such as cellulose acetate and TPU( Thermoplastic Polyurethane ) and nylon recycled from fishing nets.